- +86-18255518925

- [email protected]

HORIZONTAL TABLE CNC GROOVING MACHINE

Horizontal V Grooving Machine

Products Description

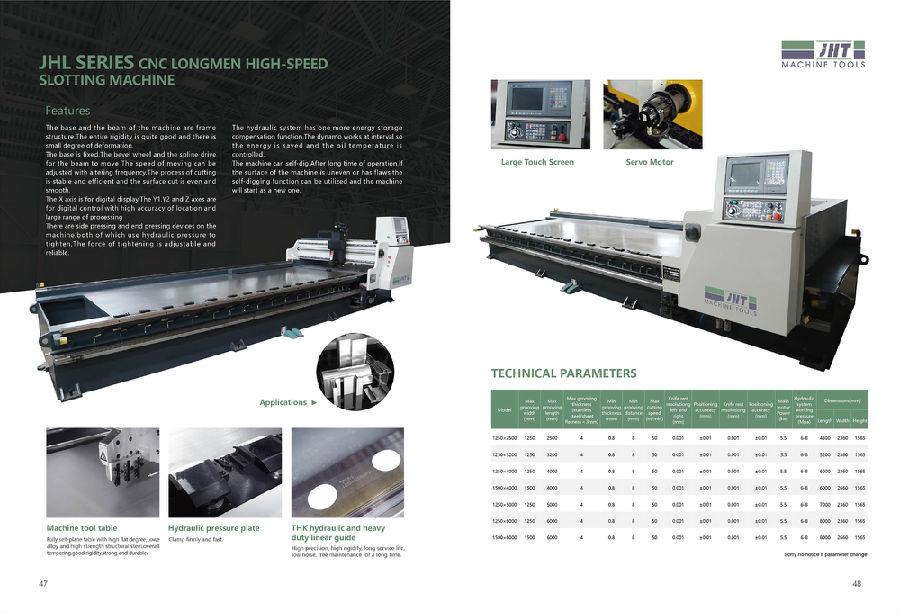

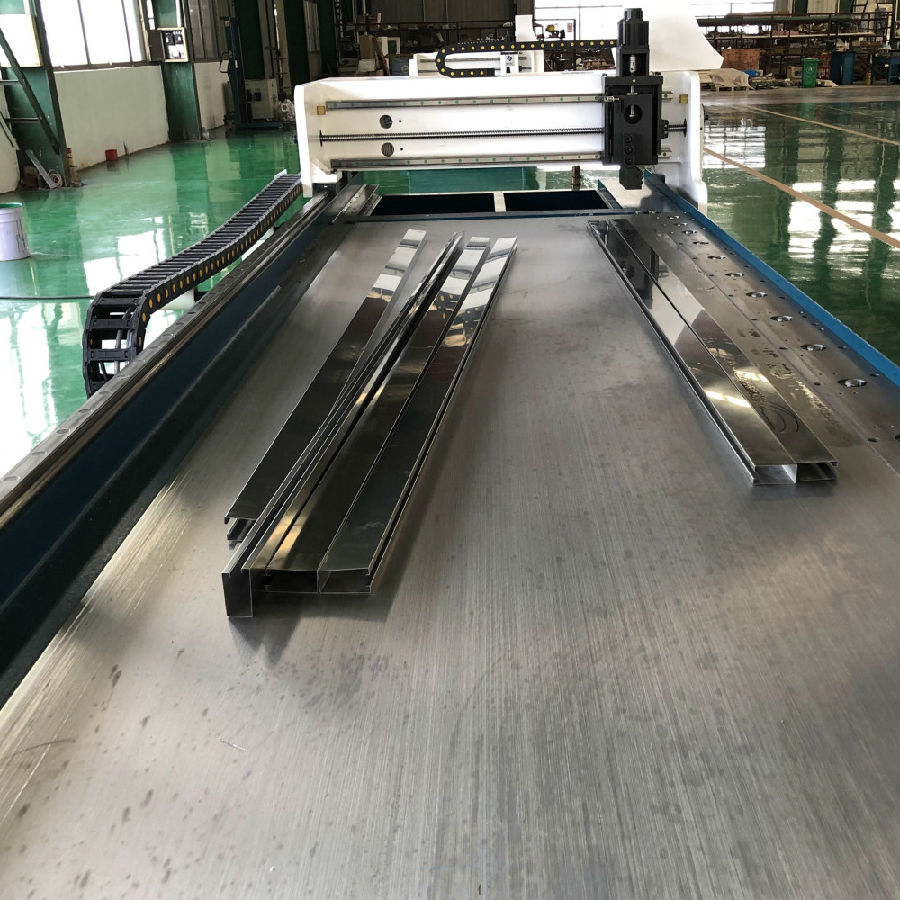

Machine bed: The machine tool is welded with high-quality steel plates, and the welding stress is eliminated by thermal aging treatment. It has strong stability, high strength and superior seismic performance, ensuring the long-term accuracy of the machine tool. Tool holder: The tool holder seat is made of high-quality die steel. After quenching and tempering treatment, the guide rails and sliders are precisely milled, and the adjustment device is designed. The feed rate is driven by the ball screw and the servo motor, and the sliding is dragged. The block moves up and down to feed, with fast feed speed and high feed accuracy. The planing tool is composed of four knives, which are precise and have good grooving effect. Workbench: Super large workbench design, laying flat materials more complete, and running smoothly during work. Independent pressure plate: auxiliary pressure plate, enhance the pressing force of the workpiece, and ensure that the starting position of the knife and the table are close. It can be moved left and right according to the needs of work. Operation interface: The control center of the machine tool can be rotated 270 degrees for easy operation. The touch screen is Weilun's latest large-screen color interface. Equipped with control buttons. Pause switch: the machine tool can be paused in the execution of cutting tasks, and press it again to continue cutting Emergency stop switch: the machine can be used to stop the machine with an emergency brake in case of emergency Spindle drive assembly: It is composed of a servo motor and a gear transmission. The servo motor has a large starting torque, fast starting and stopping speeds, and the gear transmission has high efficiency and rigidity relative to the belt drive. The tool holder will not vibrate during planing.

Performance

High efficiency,energy saving,environmental protection.

Fast and grooving precise positioning.

Adaptive forward,can adapt to different status of sheet metal.

High precision workable.

Easy operation,stable performance and reliable.

After use fixture of knife,knife change need not reset to zero.

Features .

· JHL series Horizontal V Grooving Machine base and beam are designed with frame structure. The working table is made of 60mm Q345 low-alloy high-strength structural steel. The frame is made of Q235 steel plate. The machine tool has good overall rigidity and durability.

· The bed is tempered with natural gas to eliminate welding stress and reduce equipment deformation. Sandblasting guarantees excellent paint finish.

· JHL Horizontal V Grooving Machine adopts precision copper gear and helical rack drive, supplemented by Taiwan Shangyin roller heavy-duty linear guide. The moving speed can be adjusted by frequency conversion, and the cutting process is smooth and efficient. The first-level transmission of the motor is driven by a V-belt. Due to the tensile force of the V-belt, the impact force during emergency stop and rapid return is reduced, which ensures the flexible operation of the equipment and extends the service life of the equipment.

· The JHL Horizontal V Grooving Machine uses a SFSR Silent Ball Screw and a QH Silent Rail to ensure high accuracy.

· The JHL Horizontal V Grooving Machine is fixed by Hydraulic clamping system, which can fast groove and guarantee strong clamping. Hydraulic clamping prevents plate crushing.

· The JHL Horizontal V Grooving Machine uses four cutters to machine “V” grooves, so the cutting amount is evenly distributed, reducing deformation of the machined part. And the optional micro cooling system can prolong the service life of the tool and reduce the production cost.

· The JHL Horizontal V Grooving Machine can be machined both longitudinally and laterally, and has a process to achieve the “front and back” processing function of the plate.

· With this V Grooving Machine, you can do it with only the input keyboard and processing program. According to different operators and materials, the knob can be used to adjust the processing speed, which is convenient for the operators.

· The status of the process in processing can be understood through the display. Sensors are used to ensure the safety of operators.

· The alarm message appears on the display when the equipment is abnormal, which is easy to repair.

When using the V Grooving Machine to process, only labor is required for the placement and removal of the workpiece, so labor can be saved.

· The JHL Horizontal V Grooving Machine table has a self-healing function. During use, customers can plan the table according to their own requirements to ensure processing accuracy.