- +86-18255518925

- [email protected]

VERTICAL TWO HEAD CUTTING CNC GROOVING MACHINE

Vertical V Grooving Machine

Description · The vertical CNC V grooving machine

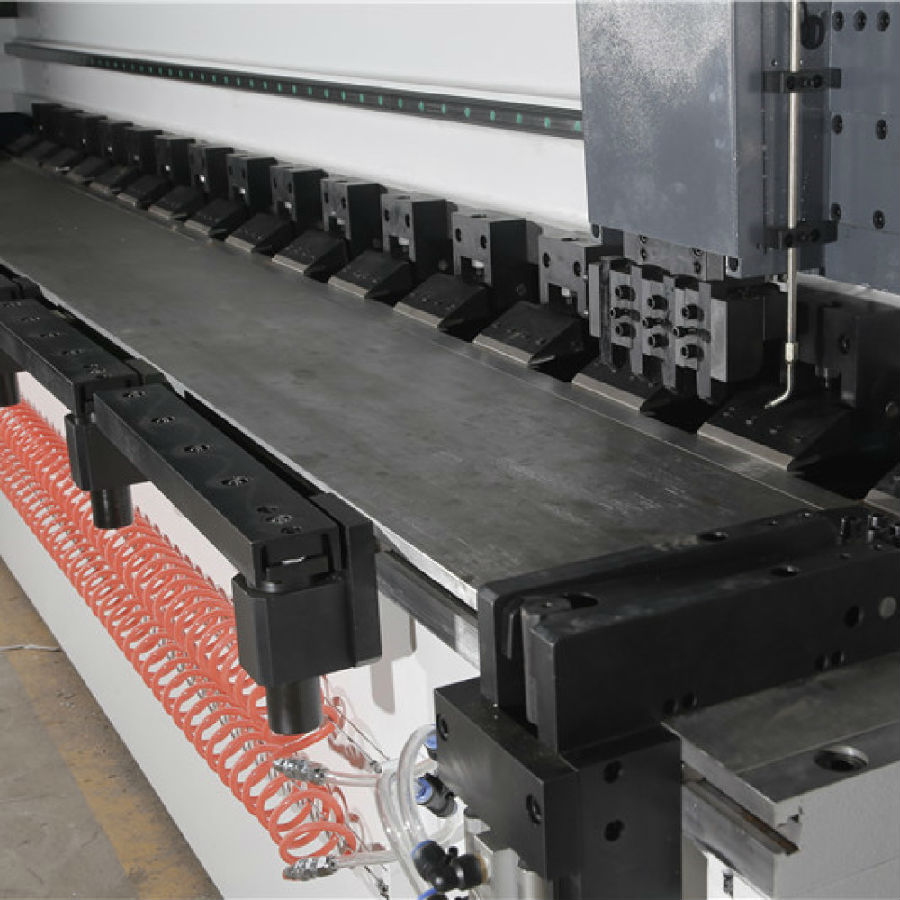

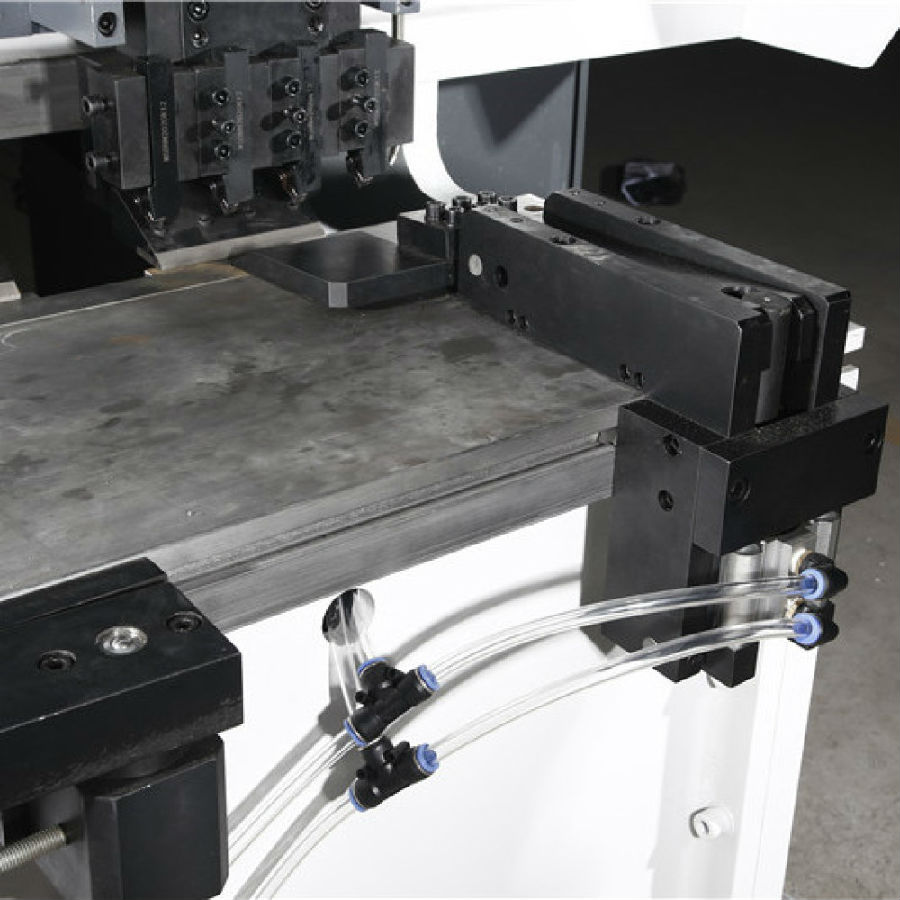

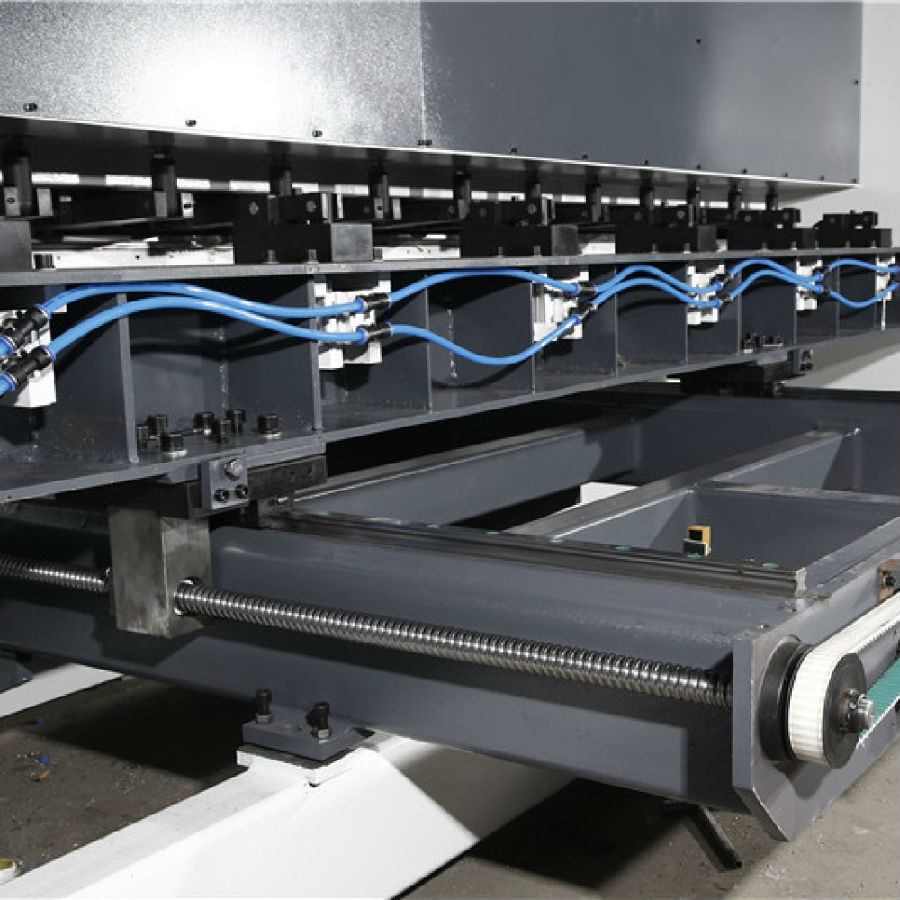

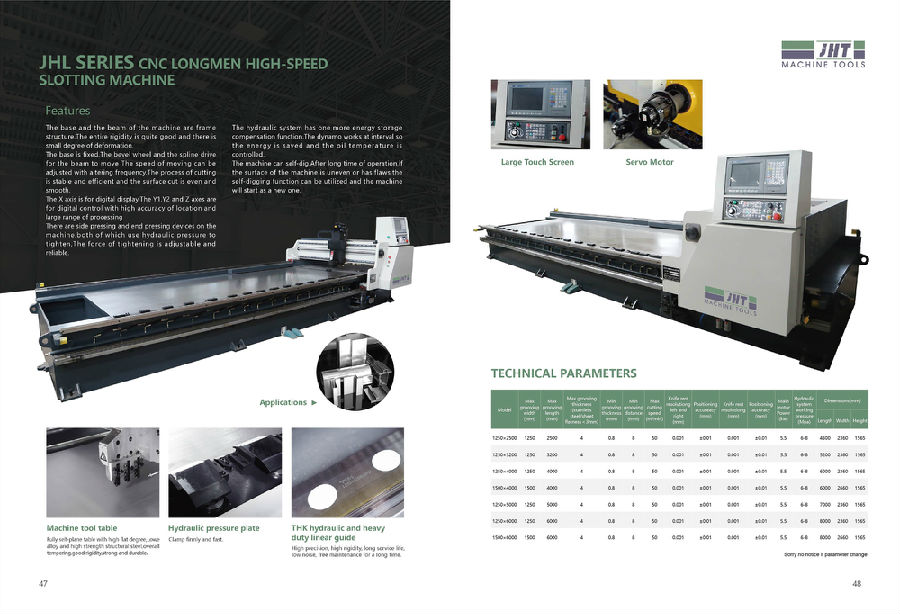

The vertical CNC V grooving machine’s working table is narrow. The planer is fixed in a straight line position to the working table. Variable factors can be well-controlled, so the distance accuracy from the tooltip to the table can be controlled in the range of 0.02mm. When the vertical CNC V grooving machine is working, the tool holder part moves back and forth. Its weight is about 60 kg.

Vertical V groover machines have a dozen separate pressing plates and more than fourteen independent clamps for automatic clamping. Plates of all sizes can be processed. What’s more, the vertical V groover machine both can do horizontal and vertical grooves. The minimum workpiece size is 8mm*8mm. The vertical sheet metal grooving machine’s work surface is high-quality mold steel which through overall heat treatment after a grinder refined. Its surface fineness achieves the effect of the mirror. Therefore, the processed products are clean and smooth.

CNC Controller

1. Lower maintenance cost 2. Shorten training time

3. Avoid collision 4. In any axial direction can be installed with grating ruler

5. Responsive time for acceleration/deceleration: 0.5US

6. High-speed positioning of main shaft

7. With retraction function

8. Intellective fault alarm and troubleshooting function

9. PLC interrupt function: fixed scan time 10ms

10. All axes open-loop control with feedback function

11. The servo motor torque can be read and displayed

12. The acceleration and deceleration control curve is superior to other numerical control.

13. With DC power input module

14. With SSR external input signal plate

15. Easy wiring, low wiring cost